In recent years, an innovative material has gained significant popularity in the construction and urban design sector: WPVC.

This acronym, which stands for Wood-Plastic-Vinyl Composite, represents a versatile and sustainable solution that is transforming the design and construction of cities worldwide.

Let’s explore what WPVC is, how it differs from the more well-known WPC (Wood-Plastic Composite), and how LAB23 is using this material to revolutionize urban projects throughout Europe.

What is WPVC?

WPVC is a material composed of a blend of wood, plastic and PVC (polyvinyl chloride), which is pressed and molded to create sheets or profiles.

This combination of materials offers a range of distinct advantages that make it an ideal choice in various construction and design contexts.

But what are the differences from WPC?

Differences between WPC and WPVC

The main difference between WPC and WPVC lies in the composition of the plastic used. In WPC, the plastic component is polyethylene, whereas in WPVC, it is PVC.

This fundamental difference gives WPVC some unique characteristics.

PVC is known for its resistance to weathering, sunlight, moisture, and biological attacks, making WPVC an exceptionally durable material in outdoor environments.

Furthermore, WPVC offers greater dimensional stability compared to WPC, making it ideal for applications where temperature and humidity variations can be significant.

Its superior mechanical strength allows it to be used for projects requiring higher load-bearing capacity, such as flooring, fences and architectural structures.

But the benefits of WPVC don’t stop there; let’s explore them in more detail.

Benefits of WPVC

WPVC has several significant advantages that make it an attractive choice for urban projects:

- Sustainability: WPVC combines recyclable materials, reducing its environmental impact compared to traditional materials like chemically treated wood.

- Durability: thanks to its resistance to weathering and dimensional stability, WPVC requires less maintenance over time, saving time and resources.

- Versatility: the material can be used in a variety of applications, including flooring, fencing, cladding, and urban furnishings, allowing designers to express their creativity in entirely new ways.

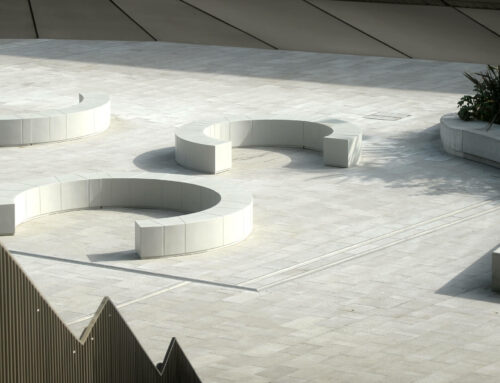

Applications of WPVC in LAB23’s Urban Projects

LAB23, a Venetian company with extensive experience in the urban design sector, has embraced WPVC as a key material for its innovative projects.

By using WPVC, LAB23 has created a range of city solutions that blend aesthetics, functionality, and sustainability.

Specifically, in LAB23, WPVC is used in various benches designed by GIBILLERO Design: Armonia Eco, Moko Eco, Deacon Eco, and Marilyn Eco.

ARMONIA ECO embodies the elegance of sustainability, with its weather-resistant galvanized steel structure and an eco-friendly seat made of expanded PVC profiles and wood flour, recycled and certified as “Second Life Plastic.”

MOKO ECO is a design bench inspired by traditional park benches but made with modern and ecological materials. It consists of expanded PVC profiles and 100% recycled wood flour, with galvanized steel legs for corrosion resistance.

DEACON ECO is an eco-friendly bench with a galvanized steel structure, weather-resistant, and featuring a seat made of expanded PVC and wood flour, a recycled and self-extinguishing material. Certified as “Second Life Plastic,” it has a clean design with four PVC slats and contoured legs.

MARILYN ECO focuses on sustainability, with a weather-resistant galvanized steel structure and a seat made of expanded PVC and wood flour, a recycled and self-extinguishing material, certified as “Second Life Plastic.”

Its light and essential design make it suitable for outdoor spaces and private gardens, also available in single and double-seat variants.

Discover more about our proposals for the city of the future and contact us for more information or a personalized quote.